Regular Lab Equipment Calibration – Why It Is a Mandatory Requirement in Textile Testing?

In the testing industry, the accuracy of test results is crucial for product quality control, compliance with standards, and business reputation. To ensure reliable measurements, lab equipment calibration is a mandatory step that cannot be overlooked.

1. What Is Equipment Calibration?

Calibration is the process of comparing a measuring instrument against a higher-accuracy standard to determine its deviation and make necessary adjustments. The calibration results help verify whether the equipment operates within the allowable accuracy range.

2. Why Is Calibration a Mandatory Requirement in Testing?

🔹 Ensures Accuracy and Consistency of Test Results

-

Uncalibrated equipment can lead to measurement errors, affecting test results.

-

In textile quality control, if instruments measuring color fastness, tensile strength, or elasticity produce incorrect data, businesses may misjudge product quality.

🔹 Compliance with International Standards (ISO, ASTM, AATCC, OEKO-TEX, etc.)

-

Most quality management systems (ISO 17025, ISO 9001, etc.) require equipment to be calibrated periodically.

-

Leading brands such as Nike, Adidas, and H&M mandate that their suppliers perform quality control using calibrated equipment.

🔹 Reduces Risks and Prevents Losses Due to Equipment Errors

-

Uncalibrated equipment can produce incorrect test results, disrupting production or leading to product rejections during export.

-

For example, a shrinkage tester with inaccurate readings can lead to customer complaints about product quality, resulting in financial losses and reputational damage.

🔹 Optimizes Maintenance Costs & Extends Equipment Lifespan

-

Calibration helps detect early-stage equipment issues, preventing costly repairs.

-

Proper equipment maintenance also enhances durability and ensures stable performance.

3. How Often Should Calibration Be Performed?

Depending on industry standards, usage frequency, and customer requirements, the calibration cycle can be:

-

Every 6 months: For high-precision equipment that is frequently used.

-

Every 12 months: For durable equipment with minimal environmental impact.

-

As required by customers or specific standards.

4. Choosing a Calibration Service – Why Is Thach Anh Vang the Best Choice?

Certified & Compliant with International Standards

-

Thach Anh Vang’s calibration service follows ISO 17025 standards, ensuring high accuracy and full traceability.

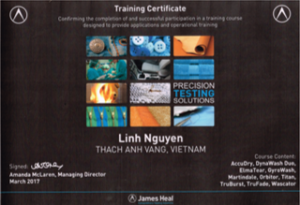

Expert Technicians Trained by Leading Manufacturers

-

Our technicians receive official training from James Heal, Miele Professional, Electrolux Professional, Mahlo, X-rite…

-

Deep expertise in textile testing and lab equipment, providing optimal calibration solutions.

On-Site Calibration – Fast and Minimized Downtime

-

Offering on-site calibration services at customer labs to reduce downtime.

-

A professional process that ensures uninterrupted equipment operation.

Comprehensive Reports & Equipment Adjustment Support

-

Providing detailed, clear, and traceable calibration reports.

-

Assisting customers in adjusting equipment to correct deviations, ensuring precise measurement results.

Lab equipment calibration is not just a mandatory requirement in testing; it is also a strategic solution that helps businesses ensure product quality, meet industry standards, and maintain a competitive edge.