Tensile Titan

Universal Tensile Strength Tester

Advanced Engineering for Reliable and Repeatable Textile Testing

Titan by James Heal is a state-of-the-art tensile testing instrument designed specifically for the textile industry. Combining precision engineering with the intelligent TestWise software, Titan delivers unparalleled accuracy, efficiency, and ease of use, ensuring compliance with global standards for fabric, yarn, and garment testing.

Key Features & Advantages

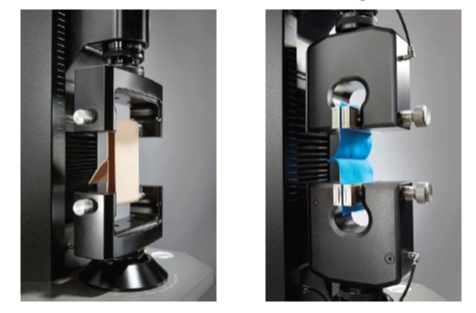

✔ Industry-Specific Design for Textile Applications

Unlike conventional universal testers, Titan is purpose-built for textiles, offering:

-

High sensitivity for delicate fabrics

-

Adjustable clamping options to prevent slippage and sample damage

-

Optimized force measurement for reliable, repeatable results

✔ Comprehensive Testing Capabilities

Titan enables a wide range of textile mechanical strength tests, including:

-

Tensile Strength Testing (ISO 13934, ASTM D5034)

-

Tear Resistance Testing (ISO 13937, ASTM D2261)

-

Seam Slippage Testing (ISO 13936)

-

Burst Strength Testing (ISO 13938, ASTM D3786)

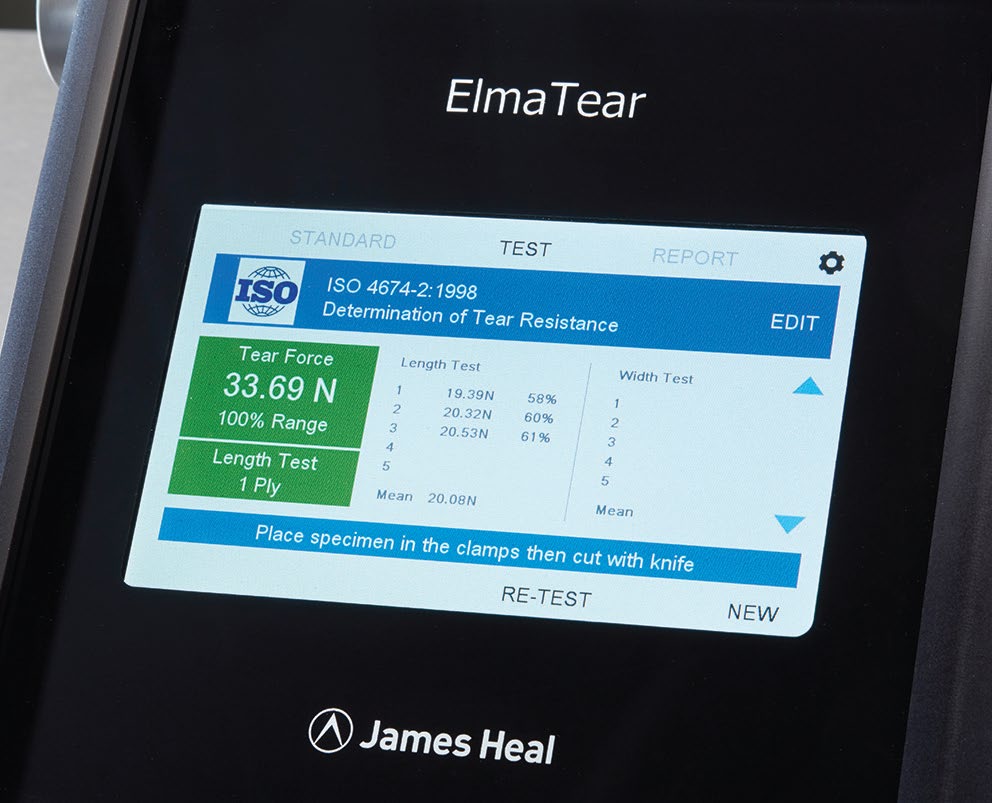

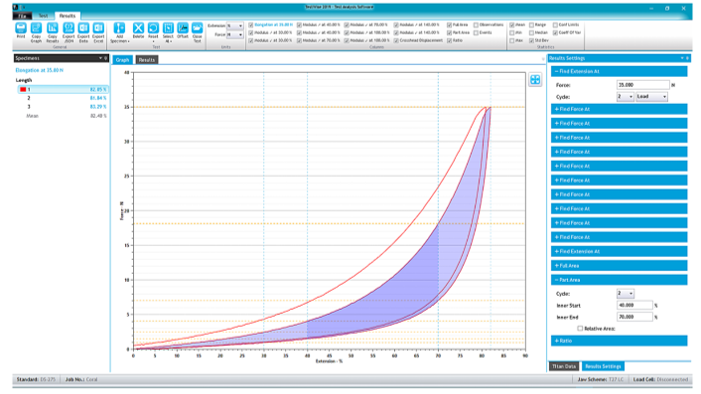

✔ TestWise Software – Intelligent Control for Consistent Results

Titan is powered by James Heal’s proprietary TestWise software, offering:

-

Pre-loaded industry-standard test methods (ISO, ASTM, AATCC, etc.)

-

User-friendly touchscreen interface with guided workflows

-

Automated data analysis for enhanced accuracy and efficiency

-

Customizable test settings to meet specific testing requirements

-

Seamless data export for quality assurance and compliance reporting

✔ Optimized for Efficiency & Operator Usability

Designed to enhance productivity in textile laboratories, Titan features:

-

Quick-change grips and fixtures for effortless test transitions

-

Automatic sample detection & test initiation to reduce manual errors

-

Compact, durable construction for high-throughput testing environments

The James Heal Commitment to Excellence

With decades of expertise in textile testing solutions, James Heal ensures that Titan meets the highest standards of accuracy, repeatability, and compliance. Whether for fabric manufacturers, apparel brands, or independent testing laboratories, Titan provides the confidence needed to uphold global quality standards.

Feature & Advantage

Accuracy, efficiency and ease of use

Cost efficience: pre-loaded 700+ test methods and easy to upgrades* for TestWise software with latest revision

AUTOMATIC TEST PARAMETERS SETUP

Faster testing: Easy to use - quick-change load cells and jaw face

Specification

| ITEM | TITAN5 | TITAN10 |

| Measuring Principle: | Constant Rate of Extension (CRE) | |

| Capacity (Tension & Compression): | 5000 N, 5kN, 500kgf and 1100lbf | 10000 N, 10kN, 1000kgf and 2200lbf |

| Load Cells: | Up to 3 load cells can be configured from a choice of five (5): 5000 N 1000 N or 500 N (not 1000N and 500N) 100 N or 200 N (not 200N and 100N) |

Load Cells available: 10000 N, 5000 N, 1000 N, 500 N, 200, 100 N |

| Test / Return / Jog Speed: | 1 – 2000mm/min | |

| Accuracy of Load Cells Class: | 0.5 (±0.5%) from 2 – 100% of load cell capacity | |

| Speed Accuracy: | ± 0.005% | |

| Maximum Stroke: | 560 mm – Maximum usable extension with T27 jaws fitted | 700 mm – Maximum usable extension with T37 jaws fitted |

| Total Vertical Stroke: | 700 mm – Maximum movement of the head between limit switches when no jaws are fitted | 980 mm – Maximum movement of the head between limit switches when no jaws are fitted |

| Positional Accuracy: | ± 0.00125mm | |

| Calibration: | Load Cells: ISO 7500-1 (UKAS accredited) & ASTM E4 Instrument: ISO 7500-1 & ASTM D76 |

|

| Safety: | CE marked (complies with Machinery, Low Voltage & EMC Directives) | |

Sign up for advice

- Hotline0938 078 338

- emailinfo@thachanhvang.com