Preventive Maintenance

Preventive Maintenance – Ensuring Stable Operations & Minimizing Downtime

In the textile industry, the stability of machinery and equipment is critical to maintaining production quality and operational efficiency. Unexpected breakdowns can result in significant losses in time, raw materials, and production costs.

At Thạch Anh Vàng, we provide preventive maintenance services to help factories:

🔹 Minimize Downtime – Early detection of potential issues allows for timely maintenance, preventing sudden equipment failures that could disrupt production schedules.

🔹 Maintain Equipment Performance – Regular inspections, adjustments, and optimization ensure stable machine operation and precise testing results.

🔹 Reduce Repair Costs & Extend Equipment Lifespan – Proactive maintenance helps prevent major failures, reducing costly emergency repairs and the need for frequent part replacements.

🔹 Ensure Compliance with Testing Standards – Routine inspections and calibrations keep laboratory equipment accurate and fully compliant with international quality standards.

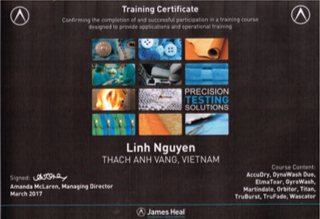

With a team of factory-trained and authorized technicians from leading brands such as James Heal, Miele Professional, Electrolux Professional, X-Rite, and Mahlo, Thạch Anh Vàng is committed to delivering specialized maintenance solutions that ensure smooth operations, optimize costs, and enhance your factory’s competitive edge.