Why Stretch & Recovery Properties are more and more popular?

Stretch & Recovery Properties

In the modern fashion industry—especially with product lines like sportswear, activewear, athleisure, stretch denim, underwear, and comfort-focused daily wear—the Stretch & Recovery properties of fabric plays a vital role in the wearer’s experience.

1. Increasing Consumer Demand for Comfort

Garments worn close to the body, such as leggings, sports bras, and stretch jeans, must fit snugly, stretch comfortably, and retain their original shape after wearing, washing, and movement. If the fabric stretches excessively and does not recover, the garment quickly loses shape and value.

2. Brands Prioritize Durability and Brand Image

Stretch capability is not only about comfort—it also represents a critical quality index reflecting a brand’s investment in product performance. Particularly in high-tech fashion collections, Stretch & Recovery Properties have become a USP (Unique Selling Point) that differentiates products from competitors.

3. Stricter Standards from Global Brands

Brands like Nike, Adidas, Lululemon, Uniqlo, and Decathlon have their own testing methods for Stretch & Recovery Properties, based on international standards such as ASTM D3107, ASTM D2594, or ISO 14704. Meeting these requirements is essential for entering global supply chains.

4. New Materials & Innovative Designs Demand Deeper Testing

With the rapid development of synthetic fabrics blended with Spandex, Elastane, Lycra, etc., stretch properties have become key technical criteria. It’s not just about elongation, but also recovery rate, delay, and stretch-recovery cycles—helping R&D and QA teams evaluate true material performance.

Key Factors Affecting Stretch Recovery Properties

Fabric Type & Fiber Content

Stretch fabrics typically contain Spandex, Elastane, Lycra, or Polyurethane. The type of fiber and blending ratio determine the fabric’s stretch and recovery capabilities.

Knitted fabrics generally stretch better than woven ones due to their flexible loop structures.

Fabric Construction & Production Methods

Weaving techniques and dyeing processes can also affect durability and recovery. For instance, knitted structures like jersey or specially designed stretch fabrics offer better recovery than coarse woven fabrics.

Washing Conditions & Usage

Washing and use (moisture, temperature, friction, and tension) can significantly affect fabric recovery. Thin or weak materials may permanently stretch or lose shape over multiple washes.

Hot washes or tumble drying can reduce recovery if the fabric hasn’t been properly stabilized.

Fabric Weight & Thickness

Heavier or thicker fabrics may have weaker recovery due to gravity and mechanical forces. Lighter fabrics are generally more elastic and retain their shape better.

Fiber Properties & Finishing Techniques

High-quality fibers like premium nylon, spandex, or lycra have superior elasticity. Fabric finishing processes (e.g., heat setting, chemical treatments) can also enhance elasticity and recovery.

Why is Stretch Recovery Properties Testing More Necessary Than Ever?

Ensures Consumer Comfort

Stretch & Recovery Properties ensures that garments like leggings, sportswear, and underwear fit well and remain comfortable, retaining their shape after multiple uses—enhancing user satisfaction and brand loyalty.

Guarantees Product Durability

Stretch & Recovery testing ensures garments are not only long-lasting but also maintain shape and quality over repeated wash cycles—especially important for sportswear, activewear, and denim.

Meets Global Standards

Major brands require these tests to meet international standards (like ISO, ASTM), ensuring their products comply with strict stretch and recovery performance throughout their lifecycle.

Evaluates Material Performance in Harsh Conditions

Stretch & Recovery tests help assess fabric behavior under stress—from washing machines and sunlight to friction and physical movement. Products must retain their shape after each use and wash.

Maintains Product Consistency

Routine testing helps manufacturers control product consistency, avoiding discrepancies in stretch and recovery between batches of the same fabric type.

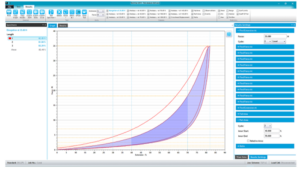

Testing on Titan 5 vs. FlexiFrame

Stretch Recovery Properties can be tested using the Titan5 universal strength tester or the FlexiFrame, depending on the stage and purpose of the test.

🟡 Titan 5 provides precise, programmable testing with full force and recovery data—ideal for R&D and standard-compliant lab testing.

🟢 FlexiFrame offers a quick, manual, visual check—ideal for production and incoming material inspection.

Thạch Anh Vàng, the exclusive representative of James Heal in Vietnam, will help you choose the most suitable testing solution tailored to your material types and brand requirements.